How Log Splitters Work

By:Marshall Brain

The simplest hydraulic device that you find in common use today is the log splitter. It contains all of the basic components of a hydraulic machine:

- An engine, normally a small four-stroke gasoline engine, provides the power for the system. The engine is attached to a hydraulic oil pump.

- The hydraulic oil pump creates a stream of high-pressure oil, which runs to a valve.

- The valve lets the operator actuate the hydraulic cylinder to split a log.

- There is also a tank to hold the hydraulic oil that feeds the pump and usually a filter to keep the oil clean.

- Valves can apply both forward and backward pressure to the piston. One type of valve is a "spool valve" because of its resemblance to a spool from a spool of thread.Let's look at some of the specifics of these components to see how a real hydraulic system works. If you take a trip down to your local building supply center or a place like Northern Tool and Equipment and look at the log splitters, you will find that a typical backyard log splitter has:

- A 5-horsepower gasoline engine

- A two-stage hydraulic oil pump rated at a maximum of 11 gallons per minute (3 gpm at 2,500 psi)

- A 4-inch-diameter, 24-inch-long hydraulic cylinder

- A rated splitting force of 20 tons

- A 3.5-gallon hydraulic oil tank

A two-stage pump is an ingenious time-saver. The pump actually contains two pumping sections and an internal pressure-sensing valve that cuts over between the two. One section of the pump generates the maximum gpm flow rate at a lower pressure. It is used, for example, to draw the piston back out of a log after the log has been split. Drawing the piston back into the cylinder takes very little force and you want it to happen quickly, so you want the highest possible flow rate at low pressure. When pushing the piston into a log, however, you want the highest possible pressure in order to generate the maximum splitting force. The flow rate isn't a big concern, so the pump switches to its "high pressure, lower volume" stage to split the log.

We'll look at hydraulic pumps in the next section.

Why we use it

The reason hydraulics are so widely used today is due to how efficient the systems are and how much pressure can be generated using them. Hydraulic systems can apply far more pressure than pneumatic systems due to hydraulics using incompressible liquids rather than gasses. This means hydraulics can easily produce up to 10,000 pounds per square inch (psi) compared to 100 psi in pneumatics (25.5 ton and 0.05 ton respectively).

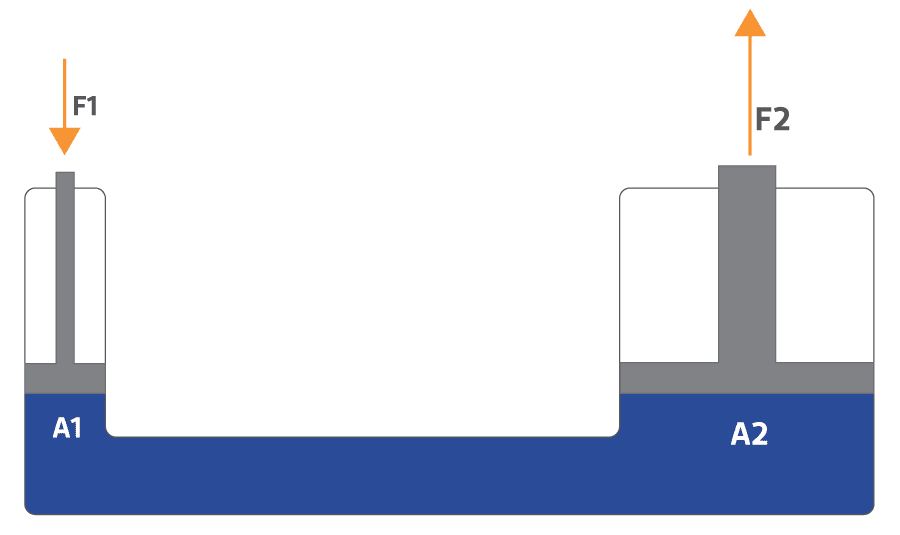

Force multiplication can be achieved by using a cylinder with a small diameter to push a larger piston in a larger cylinder. The larger cylinder will have a greater force output due to the larger surface area.

How it works

How Forest Master Log Splitter Hydraulic Work Pascal’s law (P=F/A) states that the pressure exerted upon an enclosed liquid is transmitted without loss, in all directions, to the interior of the container. This principle allows large forces to be generated with relatively little effort. As the liquid used in hydraulic systems is incompressible very little to no energy is wasted when transferring force through to the piston.

Incompressible liquids ensure the pressure applied from one end (F1) is transferred and equal to the pressure at the other end (F2) however, this means that to move a piston with a larger area (F2) the smaller piston will have to move further (F1).

Pascal’s Law Equations

Pressure = Force / Area

F1/A1=F2/A2

F2=(F1*A2)/A1

Hydraulic Pressure Multiplication Real-world example, FM10D-7-TC 7-Ton Log Splitter.

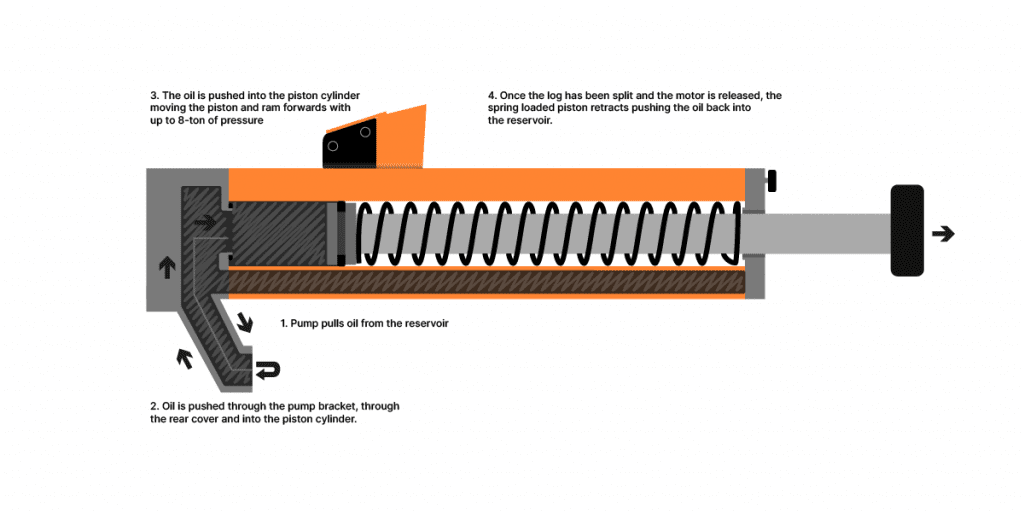

- 2200 W Electric motor powers the pump to pull oil from the reservoir.

- Oil is pushed through the pump bracket into the piston cylinder.

- Oil is pushed into the piston-cylinder moving the piston and ram forwards.

- Once the log has been split and the hand lever is no longer engaged, the spring-loaded piston will retract returning the ram and oil to their original positions.

Advantages

- Very efficient transfer of energy

- Can be either manual or powered systems

- Able to multiply input forces

- Self-lubricating

Disadvantages

- Sensitive to the environment (temperature)

- Not as effective over long distances

- Small leaks can cause significant issues with the operational efficiency of the system

- If the pressure is too high for the machine/system this can cause accidents or the machine to fail.

Conclusion

Hydraulics is a very useful and powerful technology that is almost unrivalled in pressure generation to size and efficiency, making it ideal for the application of heavy-duty machinery such as log splitters. They are not perfect systems however as if not cared for properly these systems can form a small fault that can be fatal to its operation

No comments: